- Home

- Precision CNC Machining

- Capacity

- Equipment List

In the machining industry, quality of machining of precision components are especially important. But it is difficult to produce high quality products only with good technique of precision machining personnel or normal processing machines. The machining precision and stability of normal machines can not ensure the accuracy of parts. During the machining process, both manual and mechanical factors can cause high rejection rate of workpiece. Thus, in order to product products with high precision, high-end equipment is quite important. The equipment with high degree of automation can reduce personal error. High precision equipment features good machining consistency, stable quality and appearance, low rejection rate and high production efficiency.

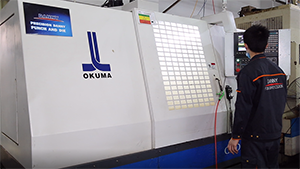

We are equipped with 66 processing equipment, which consist of 6 CNC machines, 4 CNC machines and 17 lathes and 13 grinders.(You can find our equipment list at the bottom of the page, thank you!)

Centerless grinding machines can be sued for fine grinding of end face, excircle and conical surface of batch of shafts. It is usually used for shaft machining which has high requirements on precision. The internal and external cylindrical grinding machine is especially good at machining of highly precise parts, especially parts of materials which are heat treated and of which the hardness is special. For example, hardness of tungsten steel and alloy steel should be higher than HRC60.

The outer diameters of applicable machining targets are from Φ0.3 to Φ60. And the length is from 3MM to 2000MM. The best precision can be up to 0.0005MM.

| Equipment Name | Quantity | Accuracy |

| Taiwan Jainnher Centerless Grinding Machine 12# | 5 sets | ±0.001mm |

| Switzerland Centerless Grinding Machine 10# | 1 set | ±0.0003mm |

| Japan Micron Centerless Grinding Machine 450 | 1 set | ±0.0005mm |

| Switzerland Internal and External Cylindrical Grinding Machine | 2 sets | ±0.001mm |

| Taiwan Jainnher Centerless Grinding Machine 18# | 3 sets | ±0.001mm |

| Japan Nippei Centerless Grinding Machine 20# | 1 set | ±0.001mm |

Yukai has 8 surface grinders which can be used for grinding of complex square and round workpieces. The grinding precision can be up to 0.002mm. Besides, we are equipped with single side grinder and calender which can be used for improving flatness and reducing roughness of the surface of the workpiece. The roughness of both flat and round workpiece can be up to RA0.02um, RZ0.1um. And the flatness can be up to 0.001μm.

| Equipment Name | Quantity | Accuracy |

| Taiwan Hyfair Surface grinder 614# | 6 sets | ±0.001mm |

| Taiwan Hyfair Surface grinder 618# | 2 sets | ±0.001mm |

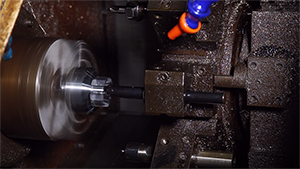

5-Axis CNC Swiss Lathes is a kind of precise machining equipment. It can accomplish combined machining of turning, milling, drilling, boring, tapping, engraving etc. It is mainly used for batch machining of precise hardware, shaft and other deformed and nonstandard workpiece.

Working parameters:Machining outer diameter: Φ1-Φ20

Max machining length: 300MM

Precision: 0.005mm~0.01mm

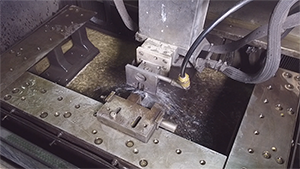

The advantages of CNC machining centers are: after one time of clamping of machining target, the NC system can realize automatic cutter selection and exchanging according to different processes. And the main shaft speed, feed rate, motion track of the cutter according to the workpiece and other auxiliary functions of the lathe can be automatically changed. It can continuously accomplish automatic drilling, spot facing, reaming, boring, tapping, milling of different sides of workpieces. The efficiency is highly improved.

Processing stroke: 950*450*500

Precision: 0.005mm

The CNC lathes are mainly used for cutting of internal and external cylindrical surface, internal and external conical surface of any taper angle, internal and external surface of complex revolution and cylinder and tapered thread of shafts and disc parts. It can also realize grooving, drilling, pore broadening, reaming and boring.

Working parameters:Max machining outer diameter: 320mm

Max machining length: 600mm

T12 cutter spacing

Highest precision: 0.003mm~0.005mm

The wire EDM can be used for wire-electrode cutting of molds and other internal parts and workpiece with complex shape. The highest precision can be up to 0.002mm.

| Equipment Name | Quantity | Accuracy |

| Japan Miyano CNC Lathe | 2 sets | ±0.005mm |

| Japan Arisawa CNC Lathe | 2 sets | ±0.005mm |

| CNC Precision Automatic Lathe | 2 sets | ±0.005mm |

| Japan Okuma CNC Lathe | 3 sets | ±0.005mm |

| American Haas CNC Lathe | 1 set | ±0.005mm |

| 15# Bench Lathe | 10 sets | ±0.05mm |

| 25# Bench Lathe | 5 sets | ±0.05mm |

| Horizontal Lathe | 2 sets | ±0.05mm |

| Taiwan Jainnher Centerless Grinding Machine 12# | 5 sets | ±0.001mm |

| Switzerland Centerless Grinding Machine 10# | 1 set | ±0.0003mm |

| Japan Micron Centerless Grinding Machine 450 | 1 set | ±0.0005mm |

| Switzerland Internal and External Cylindrical Grinding Machine | 2 sets | ±0.001mm |

| Taiwan Jainnher Centerless Grinding Machine 18# | 3 sets | ±0.001mm |

| Japan Nippei Centerless Grinding Machine 20# | 1 set | ±0.001mm |

| External Grinder/Punching Machine | 10 sets | ±0.001mm |

| Internal Grinder/Punching Machine | 4 sets | ±0.001mm |

| GM-100J | 1 set | ±0.001mm |

| Taiwan Hyfair Surface grinder 614# | 6 sets | ±0.001mm |

| Taiwan Hyfair Surface grinder 618# | 2 sets | ±0.001mm |

| High-frequency Hardening Machine | 1 set | / |

| High-frequency Heading Machine | 1 set | / |

| The following are different testers. | ||

| Salt Spraying Tester | 1 set | / |

| Roughness Tester | 1 set | 0.001mm |

| Vickers Hardness Tester | 1 set | 0.5HRC |

| Rockwell Hardness Tester | 1 set | 0.5HV |

| Japan Olympus Metallurgical Analyzers | 1 set | / |

| Japan Keyence Laser Digital Micrometer | 3 sets | ±0.0001mm |

| Japan Mitutoyo Litematic-Low-Force Measurement | 1 set | ±0.0001mm |

| Japan Keyence Altimeter | 1 set | ±0.001mm |

| Switzerland 300 Height Gauge | 1 set | ±0.001mm |

| Japan Mitutoyo Digital Micrometers 0~25 | 15 sets | ±0.001mm |

| Japan Mitutoyo Digital Micrometers 0~50 | 4 sets | ±0.001mm |

| Japan Mitutoyo Dail Calipers 0~300 | 5 sets | ±0.01mm |

| Japan Mitutoyo Height Gauge | 2 sets | ±0.001mm |

| Japan Mitutoyo RA2100AS Cylindricity Measuring Machines | 1 set | ±0.0001mm |

| German Manr Roundness Measuring Machines | 1 set | ±0.0001mm |

| Precision Gauge Block 10~291.8 | 2 sets | ±0.001mm |

| Taiwan Wan Hao 2D VMS-2010G | 1 set | ±0.001mm |

| America SD 2.5D | 1 set | ±0.001mm |

| Japan Eisen Precision Pin Gauge 1.0-10MM | 1 set | ±0.0005mm |

| England IMS 3-Coordinate Measuring Machines (CMM) | 1 set | ±0.001mm |